The Importance of Customization in Bags Packing Machines: Revolutionizing Packaging Solutions

Date:

2025-07-25

The Importance of Customization in Bags Packing Machines

In today's fast-paced industrial environment, customization in bags packing machines is not just a luxury; it is a necessity. With varying product types, sizes, and market demands, businesses are seeking tailored solutions that meet their specific needs. This article delves into the significance of customized bags packing machines, exploring how they revolutionize the packaging process and enhance operational efficiency.

Understanding Bags Packing Machines: An Overview

Bags packing machines are essential equipment in various industries, including food, pharmaceuticals, and consumer goods. These machines automate the process of packing products into bags, ensuring consistency and efficiency. However, the traditional one-size-fits-all approach often falls short, leading to inefficiencies and increased operational costs.

What Are Bags Packing Machines?

Bags packing machines are designed to fill, seal, and package products into bags, ranging from food items like snacks and grains to non-food products such as chemicals and pet food. These machines streamline the packaging process, reducing manual labor and human error.

Types of Bags Packing Machines

There are various types of bags packing machines, including:

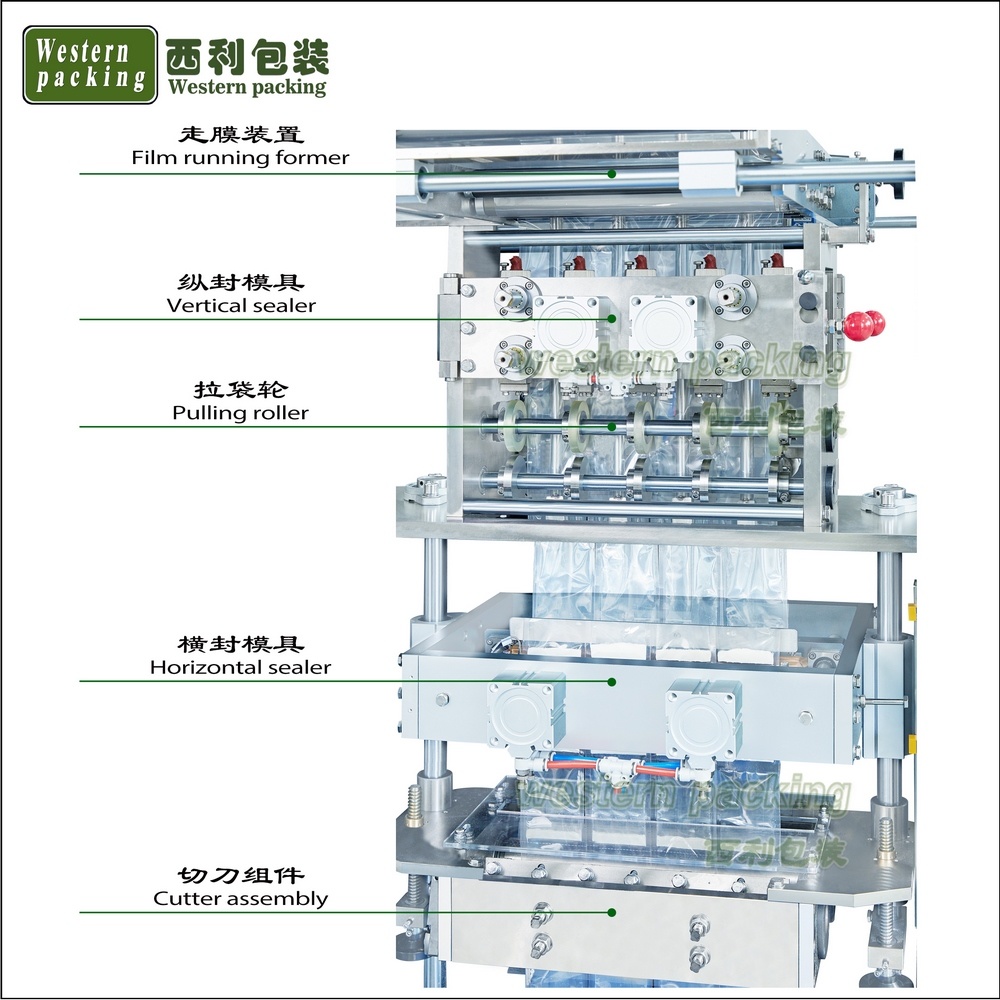

- Vertical Form Fill Seal Machines (VFFS)

- Horizontal Form Fill Seal Machines (HFFS)

- Automatic Bagging Machines

- Pouch Packing Machines

- Multihead Weighers

Why Customization Matters in Bags Packing Machines

Customization allows industries to adapt their packaging processes to fit unique product characteristics and market demands. Here are several reasons why customization is essential:

1. Enhanced Efficiency and Productivity

Customized bags packing machines are designed to optimize speed and accuracy. By tailoring the machine's settings to specific products, businesses can reduce downtime, minimize errors, and increase overall throughput. For instance, a machine designed for a particular bag size will be more efficient than a generic option that requires adjustments for every production run.

2. Flexibility to Adapt to Market Changes

The packaging industry is constantly evolving, driven by consumer preferences and regulatory changes. Customized machines can quickly adapt to these shifts, whether it's changing bag designs, sizes, or materials. This flexibility enables businesses to stay ahead of the competition and respond promptly to market demands.

3. Improved Quality Control

Quality is a critical concern in packaging. Customization allows for enhanced quality control measures, ensuring that products are packed accurately and consistently. Features such as automated checks for weight, seal integrity, and bag alignment can be integrated into customized solutions, reducing the likelihood of defects.

4. Cost-Effectiveness

While the initial investment in customized bags packing machines may be higher, the long-term benefits often outweigh the costs. Customized machines can reduce waste, lower labor costs, and improve overall efficiency, leading to significant savings over time. Additionally, businesses can avoid costs associated with product recalls or rework due to packaging errors.

5. Meeting Diverse Industry Needs

Different industries have unique requirements, from food safety standards to pharmaceutical regulations. Customization allows packaging machines to be designed with specific industry needs in mind, ensuring compliance with regulations while meeting consumer expectations. This adaptability is crucial for businesses looking to maintain their competitive edge.

Technological Innovations in Customized Bags Packing Machines

The advancement of technology has played a significant role in the customization of bags packing machines. Here are some innovations that have shaped the industry:

1. Smart Technology and IoT Integration

Smart technology and the Internet of Things (IoT) are transforming packaging operations. Customized machines can be equipped with sensors that monitor performance, alert operators to potential issues, and collect data for analysis. This connectivity enables businesses to optimize their operations continuously.

2. AI and Machine Learning

Artificial Intelligence (AI) and machine learning algorithms can enhance the customization process by analyzing production data and making real-time adjustments. This technology allows machines to learn from previous runs and optimize settings for future production, improving efficiency and reducing waste.

3. Modular Designs for Versatility

Modular designs allow businesses to customize their bags packing machines according to their changing needs. With interchangeable components, companies can easily upgrade or modify their machines without needing to invest in entirely new systems. This versatility ensures that packaging solutions remain relevant in a fast-changing market.

Choosing the Right Customization Options for Your Bags Packing Machine

When considering customization for bags packing machines, it's essential to evaluate several factors:

1. Product Characteristics

Consider the type of products being packaged. Different products may require specific handling, sealing techniques, or bag materials. Understanding your product characteristics will help guide the customization process.

2. Production Volume

The desired production volume will influence the design of the bags packing machine. Higher volumes may require more robust machinery with faster speeds, while lower volumes might benefit from flexibility and easier changeover capabilities.

3. Regulatory Compliance

Ensure that the customized machine meets all relevant industry regulations and standards. This is especially crucial in industries such as food and pharmaceuticals, where compliance is non-negotiable.

4. Budget Considerations

While customization can lead to cost savings in the long run, it's essential to set a realistic budget upfront. Evaluate the potential ROI of the investment in customization based on expected efficiency gains and cost savings.

Case Studies: Successful Customization in Bags Packing Machines

Examining real-world examples can illustrate the benefits of customized bags packing machines:

1. Food Industry Success Story

A leading snack manufacturer faced challenges with their packaging line, leading to frequent downtime and product waste. By investing in a customized vertical form fill seal machine, the company increased its production speed by 30% and reduced waste by 25%. The tailored machine included specific features for handling delicate snacks, ensuring product integrity while maximizing efficiency.

2. Pharmaceutical Industry Innovation

A pharmaceutical company required stringent quality controls for their packaging processes. They opted for a customized bags packing machine with integrated sensors for weight checks and seal integrity. This customization not only ensured compliance with regulatory standards but also significantly reduced the likelihood of packaging errors, leading to improved product safety and customer satisfaction.

FAQs About Customization in Bags Packing Machines

1. What are the key benefits of customizing bags packing machines?

Customizing bags packing machines enhances efficiency, improves quality control, reduces costs, and allows for flexibility in adapting to market changes.

2. How does customization affect production speed?

Customized machines are designed to optimize operations for specific products, reducing downtime and increasing overall production speed.

3. Can customized machines be adapted for different products?

Yes, many customized bags packing machines come with modular designs that allow for easy adjustments and modifications to accommodate various products.

4. What industries benefit most from customized bags packing machines?

Industries such as food, pharmaceuticals, and consumer goods significantly benefit from customized bags packing machines due to their diverse and specific packaging needs.

5. Are customized bags packing machines cost-effective in the long run?

While they may require a higher initial investment, customized machines often lead to long-term cost savings through increased efficiency and reduced waste.

Conclusion

In the competitive landscape of modern manufacturing, the importance of customization in bags packing machines cannot be overstated. By investing in tailored solutions, businesses can enhance efficiency, improve quality control, and adapt to the ever-changing market demands. As technology continues to evolve, the opportunities for customization will only expand, empowering industries to meet their unique packaging challenges effectively. Embracing customization is not just a strategic advantage; it is essential for sustained success in the packaging industry.

bags packing machine

Previous

The Importance of Customization in Bags Packing Machines: Revolutionizing Packaging Solutions

The Importance of Customization in Bags Packing Machines In today's fast-paced industrial environment, customization in bags packing machines is not just a luxury; it is a necessity. With varying product types, sizes, and market demands, businesses are seeking tailored solutions that meet their specific needs. This article delves into the significance of customized bags packing machines, exploring

2025-07-25

Revolutionizing Packaging Efficiency: The Hot Sauce Sachet Filling and Packing Machine

In the ever-evolving world of food packaging, the hot sauce sachet filling and packing machine stands out as a critical innovation. As consumer preferences shift towards convenience and portion control, sachet packaging has gained significant traction. This machine is designed to streamline the process of filling and sealing individual sachets with hot sauce, catering to both manufacturers and con

2025-07-23

How to Choose the Right Sauce Container for Your Packing Machine

How to Choose the Right Sauce Container for Your Packing Machine In the competitive landscape of food manufacturing, **choosing the right sauce container for your packing machine** is crucial for both product integrity and operational efficiency. Whether you are producing ketchup, hot sauce, or gourmet dressings, the container you select plays a vital role in preserving flavor, ensuring safety,

2025-07-21