- Product description

- Specifications

-

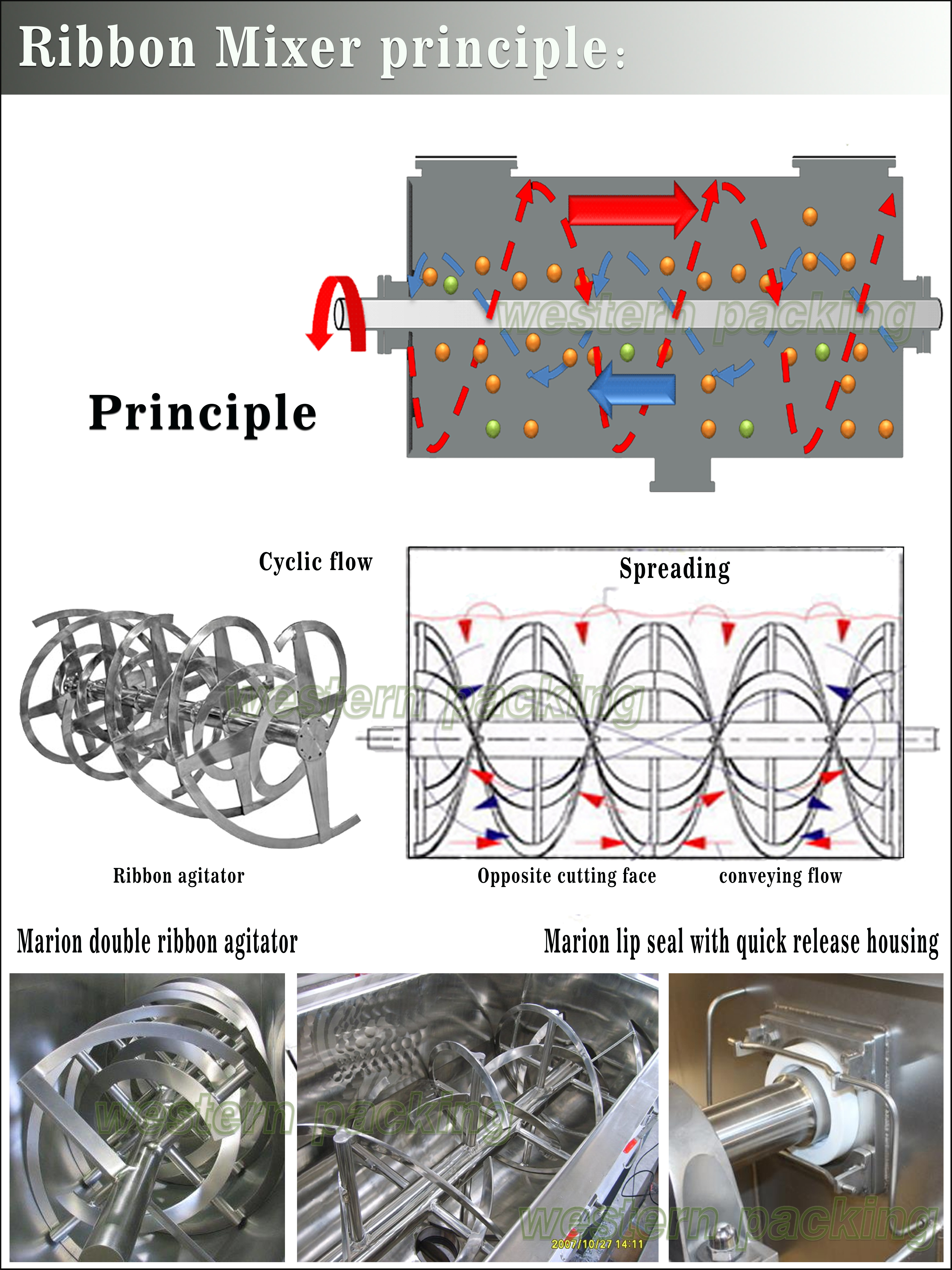

The ribbon dry powder mixer features a double-layer ribbon as its core stirring component. The outer ribbons push materials to gather at the center, while the inner ribbons disperse materials to both ends, forming a circulating convection to achieve efficient mixing of dry powders. Suitable for powders such as flour and chemical raw materials, it boasts a mixing uniformity of over 95%, strong sealing performance, and no residue during discharge. It is widely used in small and medium-sized batch mixing scenarios in food, pharmaceutical, building materials and other industries, adapting to various dry powder mixing needs.

-

Horizontal Ribbon Mixer

Main features:

- Horizontal tank body, need small space but more capacity

- Dual screw structure-the inner screw push the material from central to sides and the outer screw push the material from sides to the center to make the material effective mixing

- Gear box drive the auger shaft , low noise and low malfunction

- U-Shape tank bottom, better for material discharge and cleaning

- Pneumatic cylinder or manual butterfly valve to control the discharge exit

- All structure made by SS 304 material except motor

- Control panel simple and easy operate .With timer to set the mixing time

- It can be add the sprayer to mixer the liquid material for color or perfume, need extra cost

GENERAL DESCRIPTION:

- This machine is used to blend dry powder or small granule by two steel ribbons inside. The two ribbons

- will drive powder flow from in different direction and turn up and down, so the powder will get equally

- mixed in short time. All the machines are made of SUS 304. Extra device for heating or cooling, liquid

- spraying is a available. It’s widely used in food, chemical, pharmaceutical powder industries.

/Model

WPW-300

WPW-500

TDW-1000

TDW-1500

TDW-2000

TDW-3000

Effective Volume

300L

500L

1000L

1500L

2000L

3000L

Fully Volume

420

650

1350

2000

2600

3800

Fullness Coefficient

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

Turning Speed

53rpm

53rpm

45rpm

45rpm

39rpm

39rpm

Total Weight

660kg

900kg

1380kg

1850kg

2350kg

2900kg

Total Power

5.5kw

7.5kw

11kw

15kw

18.5kw

22kw

Length(L)

1530

1550

1900

2150

2300

2420

Width(W)

1250

1350

1800

2020

2150

2300

Height(H)

1300

1350

1580

1700

1850

1980

Power Supply

3P AC208-415V 50/60Hz

Deploy List

No.

Name

brand

country

1

Frequency converter

SIEMENS

Germany

2

Temperature controller

OMRON

Japan

3

Proximity switch

OMRON

Japan

4

Relay

OMRON

Japan

5

Power switch

SCHNEIDER

French

6

Pneumatic component

Air Tec

Taiwan

7

Gear

IBC

Germany

Material contact part 316 S/S and the bodyshell-304 stainless steel.

Dry powder mixer machine

Horizontal Ribbon Mixer

Main features:

- Horizontal tank body, need small space but more capacity

- Dual screw structure-the inner screw push the material from central to sides and the outer screw push the material from sides to the center to make the material effective mixing

- Gear box drive the auger shaft , low noise and low malfunction

- U-Shape tank bottom, better for material discharge and cleaning

- Pneumatic cylinder or manual butterfly valve to control the discharge exit

- All structure made by SS 304 material except motor

- Control panel simple and easy operate .With timer to set the mixing time

- It can be add the sprayer to mixer the liquid material for color or perfume, need extra cost

GENERAL DESCRIPTION:

- This machine is used to blend dry powder or small granule by two steel ribbons inside. The two ribbons

- will drive powder flow from in different direction and turn up and down, so the powder will get equally

- mixed in short time. All the machines are made of SUS 304. Extra device for heating or cooling, liquid

- spraying is a available. It’s widely used in food, chemical, pharmaceutical powder industries.

|

/Model |

WPW-300 |

WPW-500 |

TDW-1000 |

TDW-1500 |

TDW-2000 |

TDW-3000 |

|

Effective Volume |

300L |

500L |

1000L |

1500L |

2000L |

3000L |

|

Fully Volume |

420 |

650 |

1350 |

2000 |

2600 |

3800 |

|

Fullness Coefficient |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

Turning Speed |

53rpm |

53rpm |

45rpm |

45rpm |

39rpm |

39rpm |

|

Total Weight |

660kg |

900kg |

1380kg |

1850kg |

2350kg |

2900kg |

|

Total Power |

5.5kw |

7.5kw |

11kw |

15kw |

18.5kw |

22kw |

|

Length(L) |

1530 |

1550 |

1900 |

2150 |

2300 |

2420 |

|

Width(W) |

1250 |

1350 |

1800 |

2020 |

2150 |

2300 |

|

Height(H) |

1300 |

1350 |

1580 |

1700 |

1850 |

1980 |

|

Power Supply |

3P AC208-415V 50/60Hz |

|||||

Deploy List

|

No. |

Name |

brand |

country |

|

1 |

Frequency converter |

SIEMENS |

Germany |

|

2 |

Temperature controller |

OMRON |

Japan |

|

3 |

Proximity switch |

OMRON |

Japan |

|

4 |

Relay |

OMRON |

Japan |

|

5 |

Power switch |

SCHNEIDER |

French |

|

6 |

Pneumatic component |

Air Tec |

Taiwan |

|

7 |

Gear |

IBC |

Germany |

Material contact part 316 S/S and the bodyshell-304 stainless steel.

- Commodity name: Dry powder mixer machine

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!